Our boats utilize a simple construction principle grounded in decades of engineering, field testing, and customer feedback. The principle is simple, build bullet proof boats. In doing so, we manufacture boats that are stable, predictable, and resist compromising any of the boats external or internal components due to vibrations.

Building a boat that can withstand extreme abuse in of itself solves many of the low-quality nuances people find when buying a low-cost boat. Dampening of vibrations, noise reduction, and boat handling dramatically increase when the proper materials and construction types are used.

Aluminum types, thicknesses, and fabrication methods are all important factors that aren’t taken lightly. Rogue Jet’s boats are the finest, well-made boats in the aluminum boat industry without question.

- We employ a single source assigned, project-based manufacturing style (No assembly lines). Your boats hull is assigned to a single individual that is responsible for every aspect of the fabrication. This, by sure nature creates accountability for the project and pride in work done.

- Independent inspection of every process is used (a second independent look) ensuring the level of quality is upheld throughout the process. These independent inspections are broken down into 4 stages during the construction process and prior to the boat’s delivery.

- Meeting and exceeding the NMMA (National Marine Manufacturers Association), ABYC (American Boat and Yacht Council), and the US Coast Guard guide lines.

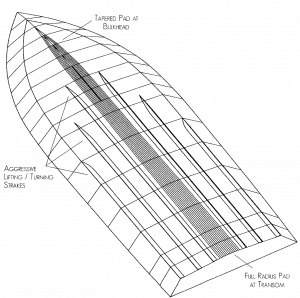

Using the 4th generation radius bottom that provides the stability and performance likened to high performance race cars. With the radius keel area, it provides a smoother rough water ride, increases the available speed, increases corning capability, and increases fuel efficiency. The Radius Tapered bottom has also enhanced the water intake flow that reduces cavitation leading to a more responsive powertrain. This type of hull requires fabrication technology that most manufacturers simply do not have. Furthermore, it is also more expensive to produce. So, in the competitive boat manufacturing business, only 4 of the current 44 manufacturers produce this advantageous 4th generation design. Furthermore, Rogue Jet is the only builder that produces the exclusive tampered-radiused hull with the surfboard keel-plate and laminar flow intake for additional safety and efficiency.

Using the 4th generation radius bottom that provides the stability and performance likened to high performance race cars. With the radius keel area, it provides a smoother rough water ride, increases the available speed, increases corning capability, and increases fuel efficiency. The Radius Tapered bottom has also enhanced the water intake flow that reduces cavitation leading to a more responsive powertrain. This type of hull requires fabrication technology that most manufacturers simply do not have. Furthermore, it is also more expensive to produce. So, in the competitive boat manufacturing business, only 4 of the current 44 manufacturers produce this advantageous 4th generation design. Furthermore, Rogue Jet is the only builder that produces the exclusive tampered-radiused hull with the surfboard keel-plate and laminar flow intake for additional safety and efficiency.- Inertia and the resistance produced by water is the same resistance air produces in aircraft. In the design and engineering process, treating the properties of water and likening those properties to air transformed many aspects of the more common designs utilized today. Rogue Jet focuses heavily on these properties during the construction process.

- On most every boat Rogue Jet build’s, .250 high grade aluminum is used for the bottom unlike .190 used industry wide. In addition to this added strength component, Rogue Jet uses an additional overlay of .250 high grade aluminum in the impact zone, an area that is most likely to receive impact in the event the boat strikes an object. On models designed for Saltwater applications Rogue Jet uses 5086 Marine Alloy at the Sides, Bottom, and Transom increasing the alloy strength by more than 40% while also proving the corrosion resistance saltwater applications demand. This is how we can offer our industry leading “Life Time Hull Warrantee” and ensure customers receive a bullet proof product, every time.

- Additional components uncommon to the industry on inboards are the 6 lifting/turning strakes we put on the bottom of each hull, designed using a T-bar extrusion for absolute rigidity. Continuously welded full-length box girders using .160 high grade aluminum, .190 high grade aluminum transom, and a solid aluminum reinforcement frame at the engine compartment and intake location that adds additional strength and rigidity. In addition, Rogue Jet reinforces gunnels for mounting hardware and stepping upon, another Rogue Jet exclusive.

There has never been any room for compromise. “Your boat, built right, every time”